Reading time: 7 minutes

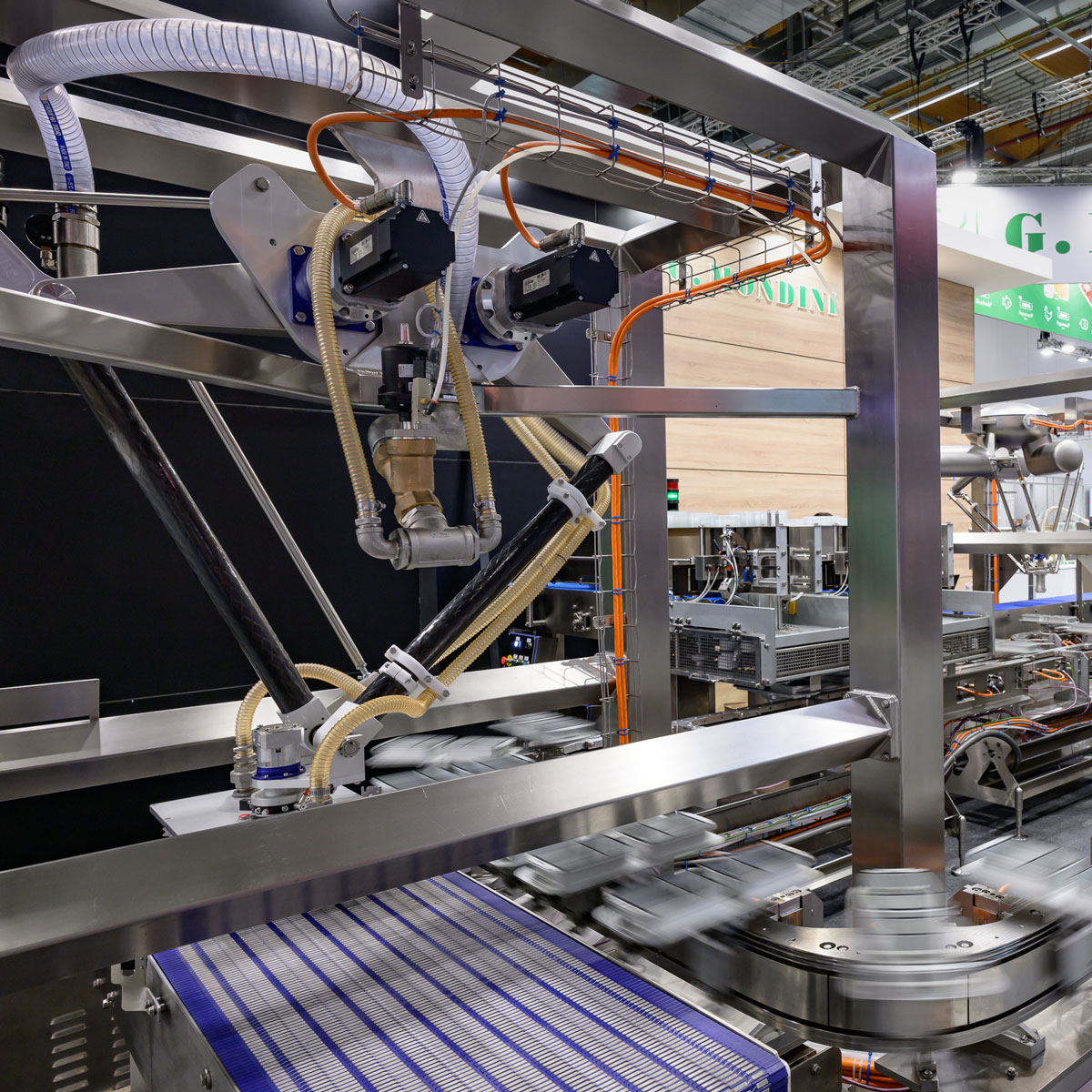

To reach this goal, processors rely on a wide range of equipment throughout the production chain from stunning and handling systems used during animal slaughter, to deboning and carcass slicing in first processing, and on to cookers, slicers, and freezers in further processing, all the way to final packaging.

While these technologies have long played a critical role to ensure food quality and safety, the integration of artificial intelligence (AI) is redefining the industry.

AI now transforms production methods by automating complex tasks, reducing reliance on manual labor and minimizing errors caused by human oversight, all while ushering in a new era of data-driven meat processing.

Elevating meat quality and inspection with AI-powered vision systems

Quality control is one of the areas where AI has made an important impact in the meat industry. Advanced AI-powered vision inspection systems can now detect defects such as contamination, irregularly shaped products or color inconsistencies with an unmatched level of precision and speed. The system can then either alert an operator or stop the line automatically, which prohibits compromised products from proceeding further into the supply chain. Through the automated inspection process, these significantly reduce the risk of human error, while monitoring production lines in real-time.

Some of the most sophisticated systems incorporate hyperspectral imaging, which combines spectroscopy and imaging technology, and these can identify and classify potential hazards with high accuracy. These detect and classify foreign materials on the surface of meat products which may otherwise go unnoticed.

More recently, AI vision systems have been enhanced with machine learning algorithms which can achieve more detailed measurements, adapt to new product types, maintain consistent performance across long production runs and operate with minimal human intervention.

These integrated vision systems empower operators with data-driven insights to make smarter decisions on the production floor. Consider a chicken nugget manufacturer dealing with costly waste levels due to inconsistent shapes, breading coverage or coloring. At high production speeds, relying on manual inspection alone is inefficient and error-prone. If fryer oil begins to overcook the breading and changes its color, the issue may go unnoticed until hundreds of units have already been produced and wasted.

AI vision systems provide real-time feedback and allow operators to act quickly. Even reducing waste by just 0.5% can generate significant cost savings over time. With accurate visual data, the team can identify problems earlier, make immediate adjustments and maintain consistent product quality.

Case studies from Cargill and Tyson Foods

Tyson Foods and Cargill, two of the largest meat producers in the United States, are now leading the way in applying AI-driven computer vision to improve their operational efficiency, reduce waste and enhance product quality across many of their facilities.

Tyson Foods historically relied on manual inventory tracking, where workers would physically count meat packages on carts and enter data by hand. In response to this time-consuming and prone to error process, Tyson adopted an AI-powered computer vision system to automate inventory tracking and improve the freshness of its products.

Today, in many of its United States plants, the company uses a combination of cameras, machine learning algorithms and edge computing to identify and record product data in real time. For example, cameras recognize the type of chicken product, while automated scales log the weight of each batch. Machine learning models then match this data to the stock-keeping unit (SKU), and an operator verifies the information on a nearby screen.

This AI system processes thousands of pounds of chicken every week, significantly increasing accuracy and operational speed, and identifies potential contaminants or foreign objects, such as conveyor belt fragments, in high-volume processing environments. The entire infrastructure is supported through Tyson’s partnership with Amazon Web Services (AWS), allowing for seamless data processing and cloud-based analytics.

Cargill is taking a similarly forward-thinking approach with its computer vision platform, CarVe, currently in operation at its Friona, Texas plant. This facility, which has already received $24 million in technology investments, serves as the launch site for a phased rollout of CarVe across additional locations in the United States.

CarVe uses AI-powered cameras to monitor meat cutting and trimming performance on the processing line. The system provides managers with instant feedback, enabling teams to refine techniques, reduce inconsistencies and minimize waste. Thanks to the continuous assessment of cutting practices in real time, CarVe supports more consistent meat yields and a higher-quality final product.

Even small improvements in yield can translate into massive benefits. A 1% gain could save hundreds of millions of pounds of beef each year, a substantial advantage at a time when U.S. cattle supplies are at historically low levels. With tools like CarVe, Cargill is helping ensure more of that protein stays within the supply chain instead of being lost to any inefficiencies.

Together, these examples highlight the powerful role AI is playing in the evolution of meat processing. By addressing long-standing operational challenges with cutting-edge technology, Tyson and Cargill are setting new industry standards for precision and performance.

AI vision systems for consistency and precision

AI-powered vision inspection systems nowadays are playing a pivotal role in improving meat production accuracy.

Take hamburger patty production as a key example. Every patty must meet strict specifications for size, shape, and thickness to ensure proper cooking and packaging. In facilities where multiple forming machines are used, maintaining this consistency can be challenging.

AI vision systems, integrated into the production line, offer a continuous stream of real-time measurements while they monitor patties as they exit the formers. These systems can detect a wide range of issues, such as double-stacked patties, edge defects or even mechanical wear in forming equipment. The data collection and analysis allows plant managers to identify machines that are underperforming or contributing to inconsistent final product.

Beyond individual machines, AI vision systems also provide valuable insights on a broader operational scale. Many platforms include software modules that generate detailed, plant-wide performance reports. These can track metrics such as product rejection rates, visual attributes (like color or texture), and conformity to quality standards.

AI vision inspection strengthens the integrity of the entire production process. By capturing and analyzing critical quality and performance data, these systems help processors uphold their commitments to food safety and operational excellence at every stage of the supply chain.

AI robotics in meat deboning: precision, efficiency and safety

Advancements in vision technology have led to the development of AI-driven robotic systems capable of cutting and deboning meat with exceptional precision. These systems adapt to different animal sizes and muscle structures, ensuring consistently correct cuts and high yield.

Modern robotic systems now use laser scanning and 3D vision technology to perform splitting operations with significant accuracy. Each carcass is scanned to create a detailed 3D model, allowing the robot to determine the animal’s length, width and anatomical structure. The robot then dynamically adjusts its cutting pressure and blade speed, optimizing each cut based on the carcass’s characteristics.

These technologies extend far beyond basic splitting. For example, in the removal of chine bones, the vision system scans the carcass down to the rib area and calculates the ideal cutting point. If a part of the carcass is damaged, the system can flag the issue or automatically adjust the operation to avoid errors.

By combining 3D imaging, laser guidance, and machine learning, AI-powered robotics now transform complex meat processing tasks, delivering greater yield and a more efficient work environment.

JBS and Volur partnership optimizes meat processing through AI

JBS USA recently announced a strategic partnership with Völur, a Norway-based company at the forefront of artificial intelligence innovation, to optimize meat processing operations. This collaboration highlights the growing role of AI in enhancing efficiency and precision, especially in the meat deboning processes.

The initiative is currently being implemented at one of North America’s most advanced beef processing facilities, located in the state of Utah. Here, AI is used to sort carcasses and generate daily cutting plans that boost the overall value extracted from each carcass.

Völur’s solution is hosted on Microsoft Azure and provides JBS USA with optimized daily plans, which are generated by leveraging AI to handle complex decision-making tasks and to increase profitability. Initially focused on daily operations, the system will eventually expand to support long-term production planning as well.

This partnership represents the latest in a series of investments by JBS to incorporate AI and computer vision technologies into its processes and supports broader goals, such as waste reduction, enhanced safety, improved efficiency and long-term sustainability.

Predictive maintenance systems and AI-driven operations

AI is also revolutionizing the meat processing sector through predictive maintenance systems. Through real-time data analysis from sensors embedded in machinery, AI algorithms can detect early signs of wear or malfunction and predict potential equipment failures before they occur. This approach reduces costly unplanned downtime and extends the lifespan of equipment, resulting in improved operational efficiency and lower maintenance costs.

These machine learning models process sensor inputs such as temperature, pressure, friction and power consumption to forecast equipment issues with precision. In high volume facilities, where a single malfunction can lead to thousands of dollars in losses, these insights are critical to maintaining continuous and efficient operations.

Lastly, AI technologies play a key role to improve broader operational workflows. AI analyzes data from sensors, cameras and performance records and, as a result, can uncover patterns that would be impossible for human operators to identify to forecast demand and streamline logistics. The result is a more resilient supply chain which reduces excess inventory and ensures timely deliveries, ultimately boosting customer satisfaction.

The promises and challenges of AI in the meat industry

AI-powered robotics are transforming meat processing by automating repetitive tasks with precision and consistency. From cutting and sorting to packaging, AI-driven systems are boosting productivity and improving workplace safety by reducing the risk of injuries caused by physically demanding work.

Yet, this technological shift comes with its own set of challenges. Data privacy and security remain key concerns, especially when handling sensitive information such as production metrics or customer preferences. To mitigate these risks, companies must implement strong cybersecurity measures and ensure compliance with evolving data protection regulations.

Another significant hurdle is the initial investment required for AI adoption. Infrastructure upgrades, staff training and access to specialized manpower demand substantial resources. For small and medium-sized processors, these barriers can be substantial. Bridging this gap will require public-sector support and greater industry collaboration to enable knowledge transfer and scalable adoption.

Despite these obstacles, the long-term benefits of AI are clear. From improving product quality to increasing efficiency and enabling smarter decision-making, AI is set to play a pivotal role in meat processing operations. As the technology continues to evolve, its applications will only expand by driving innovation, meeting growing consumer expectations and contributing to a more resilient industry.

References

Doughman, Elizabeth (19 February 2020) “Tyson uses computer vision to track chicken inventory” WattPoultry https://www.wattagnet.com/poultry-future/new-technologies/article/15530436/tyson-uses-computer-vision-to-track-chicken-inventory-wattagnet

Gilchrist, Jon, (October 2024) “AI-Driven Inspection Data fuels modern meat processors for success” Meatingpoint Magazine. pgs. 18-21. https://online.fliphtml5.com/ngtyq/vpjl/#p=1

Harvey, Simon. (5 August 2025) “AI in food – “secret sauce” solution sought for productivity” Just Food. https://www.just-food.com/features/ai-in-food-secret-sauce-solution-sought-for-productivity/?cf-view

Korsak, Anstasiia, (30 January 2023) “JBS USA to implement Volur’s AI solution to maximize carcass value and ensure optimal use of every animal”. Volur.ai. https://www.volur.ai/blog/jbs-usa-to-implement-volurs-ai-solution-to-maximize-carcass-value-and-ensure-optimal-use-of-each-animal

Meat and Poultry (26 September 2024) “The Future of Meat and Poultry processing: New Trends”. https://www.meatpoultry.com/articles/30851-the-future-of-meat-and-poultry-processing-latest-technology-trends

Nuys-Hall, Daphne. (26 June 2025) “The Rise of AI in Meat Processing: Revolutionizing Efficiency and Quality” Center for Meat Innovation and Technology. https://www.cmit.ca/the-rise-of-ai-in-meat-processing/

Peres, Rogerio, (6 September 2023) “Harnessing food tech to reshape the food industry”. New Food Magazine https://www.newfoodmagazine.com/article/194550/harnessing-food-tech-to-reshape-the-food-industry/

Stevens, Shawn K. (14 August 2025) “AI in meat processing: From neural networks to knives” The National Provisioner https://www.provisioneronline.com/articles/119279-ai-in-meat-processing-from-neural-networks-to-knives

Strategic Allies (n.d.) “Revolutionizing Food Processing with AI” https://strategicallies.co.uk/article/revolutionising-food-processing-with-ai/

Stump-Denton, Angie (9 June 2025) “Investing in the future: Cargill announces $90-million investment in automation and technology” Drovers https://www.drovers.com/news/industry/investing-future-cargill-announces-90-million-investment-automation-and-technology

Tonnesen, Anders (29 January 2025) “Smart Robots and AI make the cut in meat processing” Food Engineering Magazine https://www.foodengineeringmag.com/articles/102821-smart-robots-and-ai-make-the-cut-in-meat-processing