Reading time: 6 minutes

Does sallea represent the new standard of agriculture?

We work in cellular agriculture, which is certainly a very novel approach in our field. We do not see ourselves as the new standard, however. Our goal is to secure the future of food production in close collaboration with conventional agriculture.

There are also similarities ...

Absolutely. In conventional agriculture, animals are bred so that their meat can be “harvested”. In cellular agriculture, we start with a small number of cells. These cells then grow in a steel tank rather than in a cow – but the meat grown from the cells is also harvested. In our case, our indirectly printed scaffolds allow the cells to form a unified structure.

How sustainable is cultured meat production, if we consider rising global demand?

The United Nations Food and Agriculture Organization (FAO) estimates that global meat demand will climb up to 465 million tonnes per year by 2050, compared to the current figure of 229 million tonnes. This level of growth will be difficult to achieve with conventional meat production methods.

What conclusions do you draw from this?

Meeting this future demand solely with animal products is out of the question because of the required amount of land and the resulting CO₂ emissions. Even now, around one third of the world’s agricultural land is used for livestock farming, despite the fact that it only covers 17 per cent of our caloric consumption and 33 per cent of our protein intake1. The production of cultured meat causes up to 92 per cent fewer greenhouse gas emissions and requires significantly less land and water than conventional beef farming2.

The demand for beef is high, but its carbon footprint is huge.

One of the most straightforward ways to reduce the carbon footprint of a process is to replace fossil fuel-powered methods with electric ones. For instance, combustion engine vehicles can be replaced with electric vehicles. In cattle farming, however, the methane emitted by cows through their digestive processes contributes greatly to the industry’s poor carbon footprint. Cellular agriculture has now found a way to ‘electrify’ cows by swapping them for bioreactors.

Is cultivated meat healthier, too?

Cultivating meat cells allows for meat production without the use of antibiotics and can thus reduce the risk of antibiotic resistance. In addition to health-related and ecological benefits, there are also ethical considerations: cultivated meat and its production methods do not involve the breeding and slaughtering of animals. Conventional agriculture is already highly optimised, and further increases in production volumes will hardly be conducive to animal welfare.

At sallea, you use the term ‘3D printing’ to refer to the production of scaffolds in cell cultures. What exactly is the innovation you have brought to your field?

Generally speaking, 3D printing is an excellent process for shaping a variety of materials into precise three-dimensional structures. At the same time, the great limitation of 3D printing lies in its finite range of available materials. Substances used in food or medicine are subject to special restrictions for patient and consumer safety; they cannot be adapted to the 3D printing process at will. We therefore sought a way to allow non-printable materials to enter complex 3D structures. To this end, we developed an indirect process involving water-soluble, 3D-printed moulds made of common salt, which can be used to produce complex 3D structures – even from materials that are difficult to use in printing, such as proteins or polysaccharides.

Surely, that did not happen overnight...

We have now gone through several generations of the process, but they are all based on the same principle. First, we print common salt into negative moulds. We then pour in the desired material, such as plant proteins and polysaccharides. Next, we harden the substance by gelling, for example. Finally, we wash away the salt to obtain the desired 3D food structure without having to 3D print the material directly.

Your products are the scaffolds – edible structures that provide a framework for the cultivation of highly structured meat products.

In a hydrated state, our “ProteinPURE Scaffold” has a rather high protein content of 20 to 25% – comparable to that of a piece of meat. Its excellent nutrient profile and texture are essential for its application in cellular agriculture, because the scaffold accounts for 50 to 90 per cent of the final product. The remaining percentage is made up of the cells that grow on the scaffold and give the cultivated product its authentic taste.

Do you decide what kind of meat you will produce when the cells are extracted? Steaks or chops, for example, are streaked with sinew and fat.

We are not quite there yet. At the current stage, we have control over what species of animal it will be. If we take cells from a cow, we grow beef. In principle, the type of tissue, too, can be determined by isolated cell types, and a distinction between fat and muscle tissue is already possible today. The start-up Hoxton Farms, for instance, successfully cultivates fat.

In terms of creating flavour and texture, how much of an advantage do you have over manufacturers of plant-based meat substitutes?

We produce so-called hybrid products. At the moment, the texture and nutrient profile are mostly determined by the plant-based scaffold structure. We do not use any additives, as the cells provide the flavour.

Your product, the scaffold, is passed on to meat cultivators, who then grow meat in stainless steel tanks (bioreactors). What does this collaboration look like in practice?

Our customers are primarily meat cultivators – companies that focus on the cultivation process itself. Cultivators around the world are currently testing our scaffolds. Collaboration within the ecosystem is crucial because the entire process, from raw materials to cultivated meat, is complex. While we are familiar with such processes from the pharmaceutical industry, the latter operates to different standards. This is why a new value chain is emerging around cellular agriculture that runs parallel to that of the pharmaceutical industry. With sallea, we are contributing to this value chain.

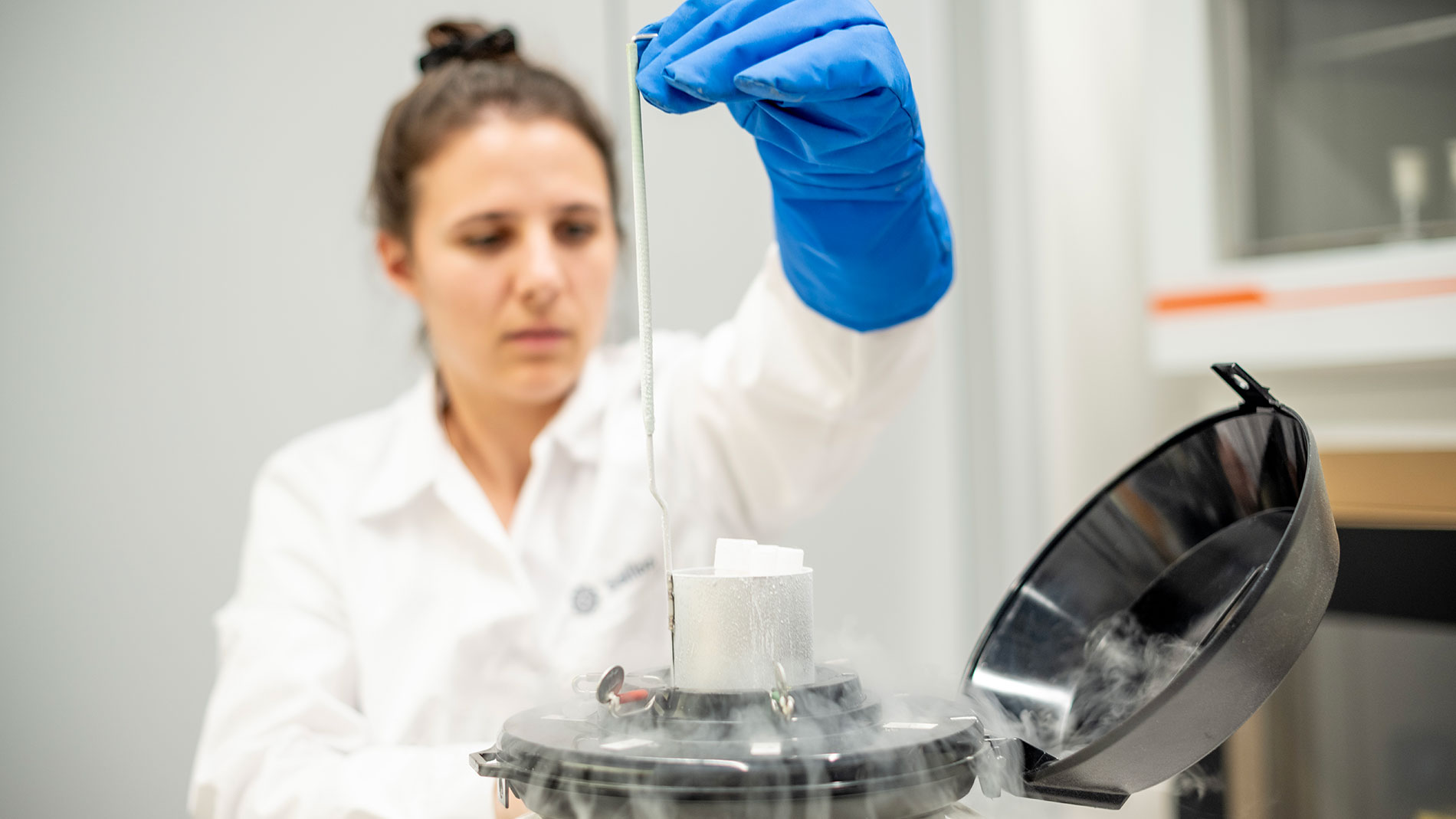

What exactly happens in the stainless steel tanks?

These large tanks are so-called bioreactors. They contain a nutrient solution with all the compounds needed for cell growth. An agitator ensures that the cells are continuously fed with nutrients; there is also a constant supply of oxygen. This helps the cells to grow and multiply as they would in a living animal. We are currently working on further developing the bioreactor, so that we can cultivate our scaffolds more efficiently and cost-effectively.

How can the process be scaled up for meat cultivators? Is it possible to give an estimate of potential production volumes?

At present, cell cultures can only produce thin layers of meat, which means that the market is limited to processed products. With sallea, we aim to lift this constraint. Our goal is to cultivate pieces that weigh 0.1 to 0.5 kg for the first time next year.

How do you address consumers’ concerns and misconceptions? What are your strongest arguments?

Fear often stems from ignorance. This is why we place great emphasis on PR and communications. We want to give future consumers a clear view of how cultured meat is produced and be transparent about the advantages and disadvantages of this new process.

How will the retail price be determined?

If our goal is to reach the general population, we need to achieve price parity with conventional products. Here, we face the same challenge as manufacturers of plant-based substitutes: animal products are often subsidised by the government. Consumers only see the subsidised price, not the actual production costs.

Conventional and cultivated production, plant-based meat substitutes – will all three coexist eventually?

Absolutely. Take the global transition to renewable energy: no single type of energy source (e.g. solar) is regarded as the only way forward; rather, the aim is to produce energy more sustainably by combining different methods.

Similarly, we need a variety of approaches for meat production, from plant-based options to cultivated alternatives, as well as innovative concepts for conventional production.

Does your start-up have long-term funding, or do you still struggle from time to time?

Developing such a novel product requires substantial capital. We successfully completed our first round of funding last September and expect to launch the next round in early February.

Redefine Bratwurst: 3D printing company profiles

Switzerland – Bern University of Applied Sciences: Child-oriented nutrition in hospitals

In a research project titled “3D-printing of food”, Bern University of Applied Sciences (BFH) explored how additive manufacturing can be used to improve the nutrition of children in hospitals. With 3D printing, meals and liquid nutrition can be crafted into visually appealing shapes and customised to for optimal micro- and macronutrient levels. Initial results show that 3D-printed pancakes – in child-friendly shapes such as spaceships and Christmas trees – can serve as attractive and nutritious in-between meal options.

Israel – Aleph Farms: World champion of cultivated steaks

Aleph Farms is a pioneer of cellular agriculture. The Israeli firm produces real meat from animal cells – without the need for animal husbandry or slaughter. In 2023, Aleph Farms became the first company to receive regulatory approval for cultivated beef and subsequently launched the world’s first cultivated steak under the name Aleph Cuts. Its goal is to produce meat in a resource-efficient manner, with projects on cell-based collagen and space nutrition also underway.

Israel – Steakholder Foods: Meat and fish from the 3D bioprinter

Founded in 2019, the Israeli company develops meat and fish alternatives using 3D bioprinting technology. After signing a multi-million dollar agreement with a government agency in 2023, Steakholder Foods has moved forward with commercialising its technology in the Middle East, including Qatar and Saudi Arabia, by supplying 3D printers and bioinks to Gulf states. The business model revolves around B2B sales of their printing technology. The launch of plant-based white fish alternatives and salmon patties marked Steakholder Foods’ entry into the consumer market.

Israel – Redefine Meat: The biggest goal

Founded in Rehovot, Israel, in 2018, Redefine Meat produces plant-based meat using 3D printers. Nozzles shape fat, proteins and liquids into precise layers that are deceptively close to the texture of real meat. Following collaborations with Givaudan and large-scale tastings, Redefine Meat expanded into Europe. Today, the company employs around 150 people and sells products such as ‘Redefine Bratwurst’. In Tel Aviv, the company’s founders impressed the public with their food truck: 90 per cent of their 600 guests believed they were eating real meat. In partnership with meat distributor Best Meister, Redefine Meat now aims to bring its plant-based steaks to restaurants all over Israel.

USA – Sugar Lab, Currant 3D: 3D confectionery still stuck in the niche

California-based Sugar Lab was hailed as the world’s first ‘digital bakery’ and set the initial standard for 3D-printed confectionery. Currant 3D went on to independently develop and commercialise the underlying printing technology. Both companies applied a binder jet process, bonding layers of sugar with an edible binder to create colourful, intricate shapes. Despite their innovative approach, commercialisation proved challenging due to high costs and a lack of scalability. Sugar Lab and Currant 3D were acquired by 3D Systems in 2022; their founders later repurchased the patents. Both brands were discontinued in early 2025.