Reading time: 5 minutes

VTEC Ingredients, founded in 2023, focuses on the procurement, biotechnological processing, and production of raw materials and additives for the manufacture of plant-based sausage, meat, and fish substitute products. To take stock, biotechnologist and managing director of VTEC Ingredients, Dr Markus Veen, was interviewed by Foodtech Now!

Meat production in Germany is now 80 times greater than that of substitute products. Many companies in the meat industry believe that tomorrow's market could grow from today's small share – and are already participating in the growth of the alternative protein market. Foodtech Now! offers a space to follow the developments of today and tomorrow and to pool knowledge, inspiration and expertise.

Dr Veen, the PHW Group has been gathering experience with alternative proteins for more than ten years. What have been the milestones during this time?

The PHW Group has been working intensively with plant-based proteins since 2013 and launched its first vegan products in 2015. With the establishment of the Alternative Protein Sources division in 2018, we made targeted investments into the development of a strong network and technological infrastructure – to complement the core poultry business. Another milestone was the establishment of the subsidiary VTEC Ingredients in 2023. Since 2024, the PHW Group has strengthened its position with VTEC Precision Foods, which focuses on the research, development, and marketing of biotechnology and process technology solutions for the food and feed industry. We also focus on strategic investments and partnerships, particularly in cultured meat and biomass fermentation, including with SuperMeat, Mosa Meat, and Kynda Biotech.

When you think of PHW, you think of poultry. However, you have not focused primarily on the production of poultry meat substitutes, but rather on the production of ingredients, raw materials and additives for plant-based meat substitutes with VTEC Ingredients. Why is that?

The market for alternative proteins is very dynamic and diverse. VTEC Ingredients enables us as an ingredient manufacturer to respond flexibly and specifically to market requirements within the PHW Group. In the field of alternative proteins, we are driven by market needs and do not limit ourselves to poultry alternatives. We work in a professional environment of suppliers, technology providers as well as customers, and so we deliberately do not limit ourselves exclusively to our own group of companies.

You see VTEC as the interface between the initial processing of raw materials and the development of finished products. Can you give us an example?

As in the poultry area, we are committed to an integrated approach to alternative protein production. Our aim is to build a competitive infrastructure along the entire value chain. We are transferring our proven vertical integration model from poultry to this new business area. This will enable us to influence quality, raw material availability, and technological development at key points.

How can we imagine the technological complexity involved in producing the ingredients? You use the facilities at the Rovita production plant in Engelsberg, for example.

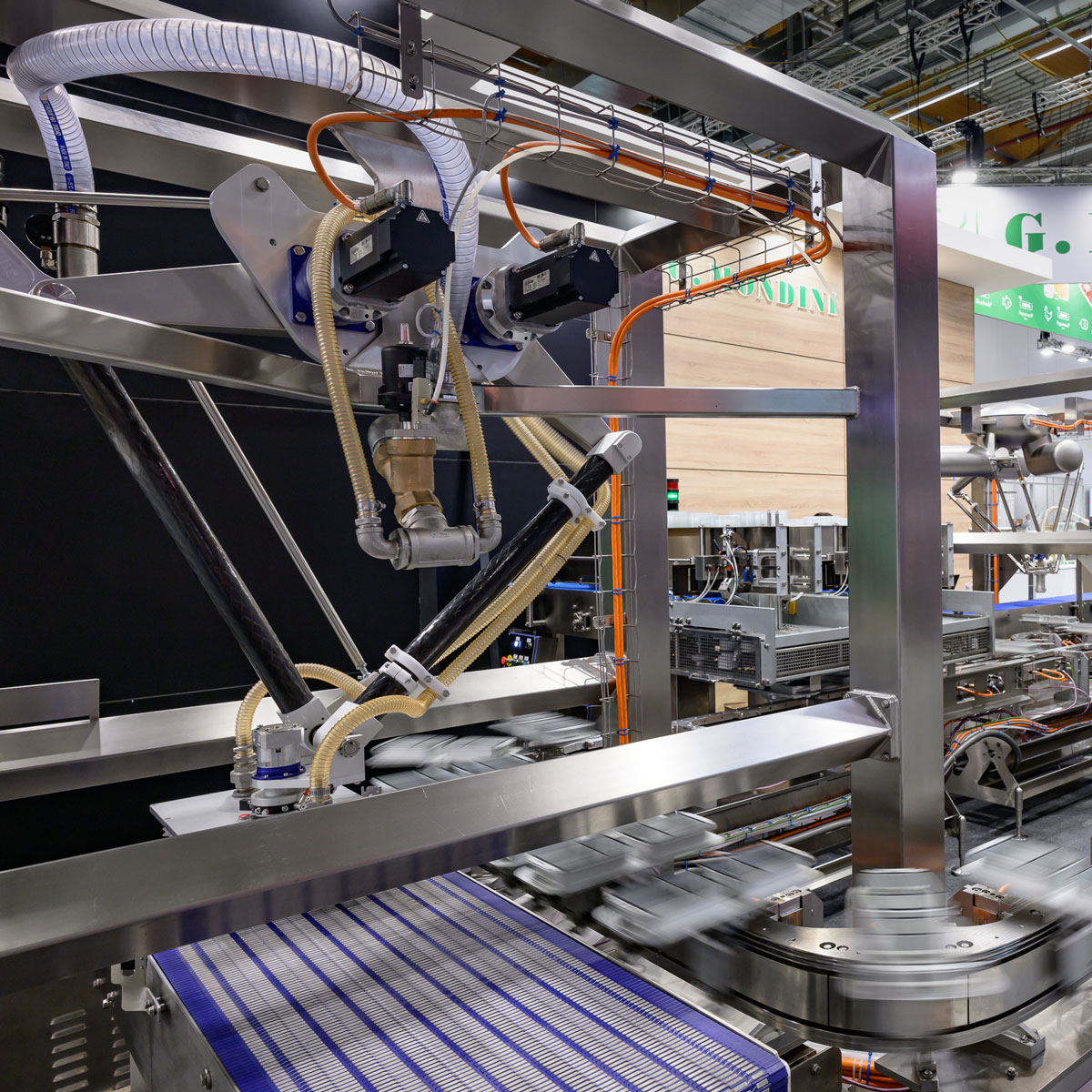

We use state-of-the-art processes at this facility, including fermentation, wet processing, drying, and mixing. The close link to this site enables us to respond flexibly and effectively/efficiently to the wishes of individual customers. Fermentation is a key technology for extracting functional ingredients and developing new sensory properties in meat alternatives. Our role at VTEC Ingredients is to intelligently link these technologies and create synergies along the entire value chain.

“Fermentation is a key technology for extracting functional ingredients and developing new sensory properties in meat alternatives.”

How demanding is research in this area? How have you organised this at VTEC?

Research into alternative proteins is challenging, as quality, taste, and cost need to be constantly optimised. The market is moving from the first generation of products with trade-offs to high-quality, sensorily-optimised alternatives. Our centre of excellence for alternative proteins at VTEC Ingredients links us with universities and research institutes. At the same time, we are developing our own key technologies, particularly in the area of fermentation, a technology which is central to the next generation of alternative proteins. Partnerships with external research institutions are essential, but we keep strategically crucial technologies and processes in-house.

What are –aside from profitability– the objectives of your work in terms of the end product: taste, texture? The ingredients? No palm oil, no soy, no flavour enhancers? What about salt and fat? Today's consumers are demanding and critical.

Our product development is always driven by market needs. Our primary aim is to develop products that are comparable to meat in terms of taste, texture, and functionality. We also consider nutritional and physiological aspects so we can provide healthy and marketable alternatives. Salt and fat content are key parameters taken into account in our developments/products.

How would you describe the difference between meat and meat substitutes from a nutritional point of view?

Our aim is to develop healthy, tasty, and marketable products based on established meat products. Consumers should be able to switch to alternative proteins without compromising on quality, taste, or health. Meeting this challenge and developing technological solutions that offer a real alternative without compromising is a key task for our research and development teams.

“Consumers should be able to switch to alternative proteins without compromising on quality, taste, or health considerations.”

What are the prospects for chicken meat cultivation? One argument that is often raised against this technology is the high energy input.

Among other things, we are invested in the Israeli start-up SuperMeat, among others, to closely monitor the development of this technology. It is still too early to make any definitive statements. As with all innovations, only scaling up will show whether cultured meat can be produced economically and energy-efficiently. In principle, we see great potential in this technology, but there are still a number of technological and regulatory hurdles to overcome before we can bring products to market in Europe.

If demand for replacement products increases significantly in the near future, how would you respond? Can existing raw materials be processed even more efficiently? Where would you start?

A key difference to animal products is that plant proteins contain a higher proportion of carbohydrates and fats. This results in by-products such as starch and oils during processing, which need to be utilised in a sustainable manner. One promising approach is to use carbohydrate fractions in biomass fermentation to convert them into valuable protein sources. Hybrid technologies will play a key role here.

As a biotechnologist focused on the production of alternative protein products, do you also see your work as having a sustainability dimension, i.e. finding solutions for a climate-friendly protein supply for a rapidly growing world population?

Sustainability is a key motivation for us. Our goal is to use biotechnology to develop an economically viable protein toolkit that intelligently combines meat and plant-based raw materials. I see this as a natural evolution – an evolution that uses modern technologies to create new opportunities for sustainable nutrition.

“Sustainability is not a buzzword for us; it is a key motivation.”

What fascinates you most about your job?

Personally, what I enjoy most about my job is the opportunity to immerse myself in scientific processes such as fermentation – and at the same time to see concrete, tangible results in the form of finished, high-quality food products. After spending many years in this industry mostly tweaking existing products, we are now seeing real innovation again. The fact that I can actively contribute with my expertise and, together with VTEC Ingredients, create new, sustainable food products is very fulfilling for me. The combination of technological depth, creative thinking, and direct influence on marketable products is what makes my daily work so exciting.